Texture determines how a fabric reads, how a product functions, and how a design is perceived under real-world conditions. Immediate tactile cues influence purchase decisions, while visual texture informs silhouette, light behavior, and perceived value.

Why texture matters in fabric and design

Texture affects ergonomics, durability, and emotional response. In apparel, texture can signal warmth, stretch, or luxury; in interiors, it sets acoustics and wear patterns. Retailers such as John Lewis and IKEA report higher conversion rates when displays use tangible textured samples. Designers who control texture from concept to production reduce rework and improve fit, drape, and photographic outcome.

Construction, surface treatment, and ornamentation

Tactile texture is the physical relief felt on touch. Visual texture is perceived through light and pattern without pronounced relief. Implied texture uses print or weave to suggest tactility. Core fabric structure dictates baseline texture: plain, twill, and satin weaves, loop and jersey knits, and mechanically bonded nonwovens each yield distinct hand and drape. Finishes such as mercerization, enzyme washes, and heat-set coatings change hand, sheen, and dimensional stability. Embossing and calendaring create raised patterns or compacted surfaces for sheen control.

Construction techniques produce texture at the garment level. Pleats create linear depth and compressibility; ruching and shirring add localized volume and elasticity; smocking introduces stretch and decorative geometry. Embellishment techniques like embroidery, appliqué, and trims add layered texture and can be functional when reinforcing stress points. Each technique has trade-offs in cost, lead time, and care requirements.

Midway through a design process, comparing methods by impact helps prioritize choices. Below is a practical reference showing common approaches, expected visual effect, compatible fibers, relative cost, and typical applications.

| Technique | Visual/Physical Effect | Best Fibers | Relative Cost | Typical Use |

|---|---|---|---|---|

| Twill weave | Diagonal texture, durable | Cotton, wool, polyester | Low | Workwear, upholstery |

| Satin weave | Smooth sheen, fluid drape | Silk, acetate, polyester | Medium | Eveningwear, linings |

| Jersey knit | Smooth face, stretch | Cotton, modal, nylon | Low | T-shirts, base layers |

| Rib knit | Linear ridges, high recovery | Wool, cotton blends | Low-Medium | Cuffs, sweaters |

| Embossing | Raised motifs, structured hand | Synthetic blends, cotton | Medium | Drapery, technical garments |

| Enzyme wash | Softened hand, muted sheen | Cotton | Medium | Casual apparel |

| Embroidery | Relief pattern, artisanal detail | Any woven/knit substrate | High | Accent panels, couture |

| Appliqué | Layered contrast, edge detail | Mixed fibers | Medium-High | Children’s wear, branding |

| Smocking | Elastic decorative texture | Lightweight cotton, rayon | High | Historical or couture styles |

| Heat-set coating | Stiffened surface, water resistance | Polyester, nylon | Medium | Outerwear, industrial textiles |

Refer to fiber compatibility and care codes when specifying finishes. Repeat testing on production machinery ensures results match lab samples.

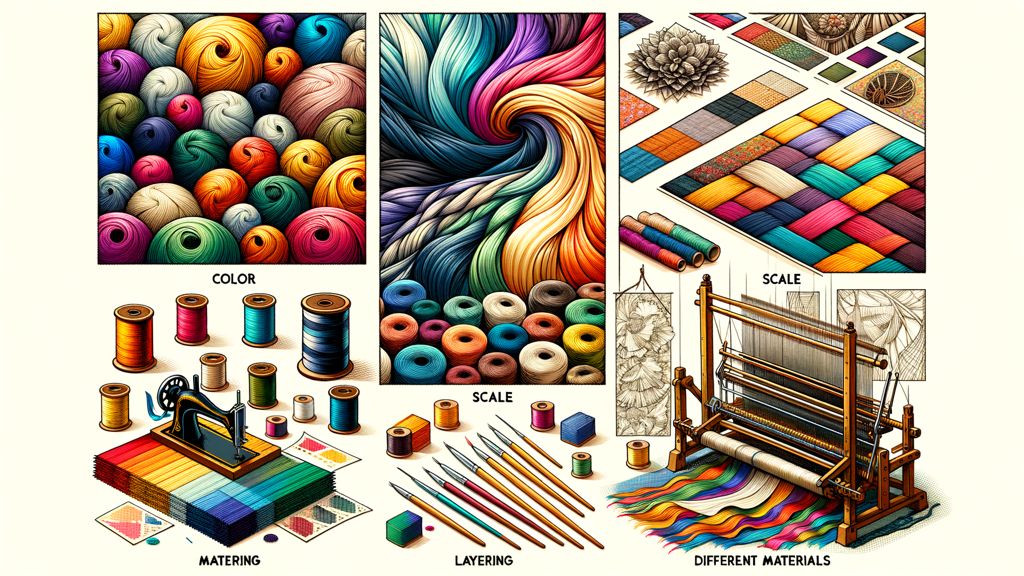

Color, scale, layering, materials, and production realities

Color interacts with texture to alter perceived depth. High-contrast color reversals accentuate weave or embroidery. Monochrome palettes emphasize shadow and highlight rather than pattern. Scale of texture relative to human anatomy matters: large motifs overwhelm small garments; fine textures can vanish at retail distance or in photography. Layering textures combines tactile interest with function; a woven coat over a soft knit base balances structure and comfort while improving thermal performance.

Material choice sharpens both aesthetic and lifecycle outcomes. Natural fibers like wool and linen have intrinsic irregularities that read as premium in slow-fashion markets but require stronger construction for longevity. Synthetic fibers offer uniform texture, enhanced abrasion resistance, and lower per-unit cost but raise questions about microplastic release. Certified organic cotton, recycled polyester, and closed-loop viscose reduce environmental impact and often improve credibility in sourcing narratives.

Sampling protocols should include full-size swatches, sewn mock-ups, and photographic captures under standardized lighting. Photographers use diffuse front light plus a low-angle rim light to reveal texture without blowing highlights. In-store display benefits from tactile zones where consumers may touch. Quality control must track pilling, seam slippage, colorfastness, and finish durability through standardized tests such as Martindale, ASTM D4966, and AATCC 61.

Digital tools accelerate iteration. CAD systems map repeat patterns and colorways onto 3D drape simulations, while physics engines predict fold behavior for given yarn properties. Simulations reduce prototype rounds but always require physical validation for hand and wear.

Costing and sourcing depend on technique intensity and supplier capabilities. Embroidery and appliqué add labor cost and lead time. Heat-setting and specialized finishes require specific machinery that may limit vendor options. Clear tech packs, annotated sketches, and measured samples reduce ambiguity when communicating with mills and trim houses.

Styling and applications vary: textured wool suiting conveys formality and warmth; textured linen upholstery signals casual durability; embroidered cushions add artisan provenance to interiors. When presenting concepts to clients, include tactile priorities, care instructions, and lifecycle expectations. A concise checklist for handoff improves clarity:

- Define primary tactile goals and functional requirements.

- Specify fibers, finishes, and acceptable vendors or certifications.

- Provide scaled mock-ups, care labels, and photographic references.

Accurate briefing and iterative sampling ensure texture-led designs transition smoothly from concept to production, balancing aesthetics, performance, and cost.